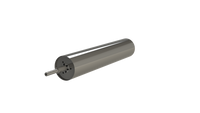

Headpully magnet

Head pulley magnets are typically installed at the end of a conveyor belt, replacing the drive drum.

Iron contaminants are attracted to the head pulley, adhering to the belt longer than other materials. As the belt moves away from the head pulley, the iron is removed from the conveyor belt, pulled away from the magnet.

These systems come in various designs, including "weak," "strong," and "particularly strong" versions, with options for longitudinal or radial execution.

Choosing the right head pulley depends on your specific needs:

For coarse iron removal, a relatively weak magnet is logical.

For maximum iron extraction or removal of small iron particles, a stronger neodymium head roll or high-gradient magnet may be preferable.

It's essential to avoid choosing a head pulley that is too strong, as this can lead to bridging and product inclusion. Bridging occurs when non-magnetic materials are trapped between the attracted iron and the belt.

Fortunately, we offer adjustable head pulleys with customizable strength settings, providing greater control over magnetic separation. This flexibility is particularly useful when running multiple products on a single production line.